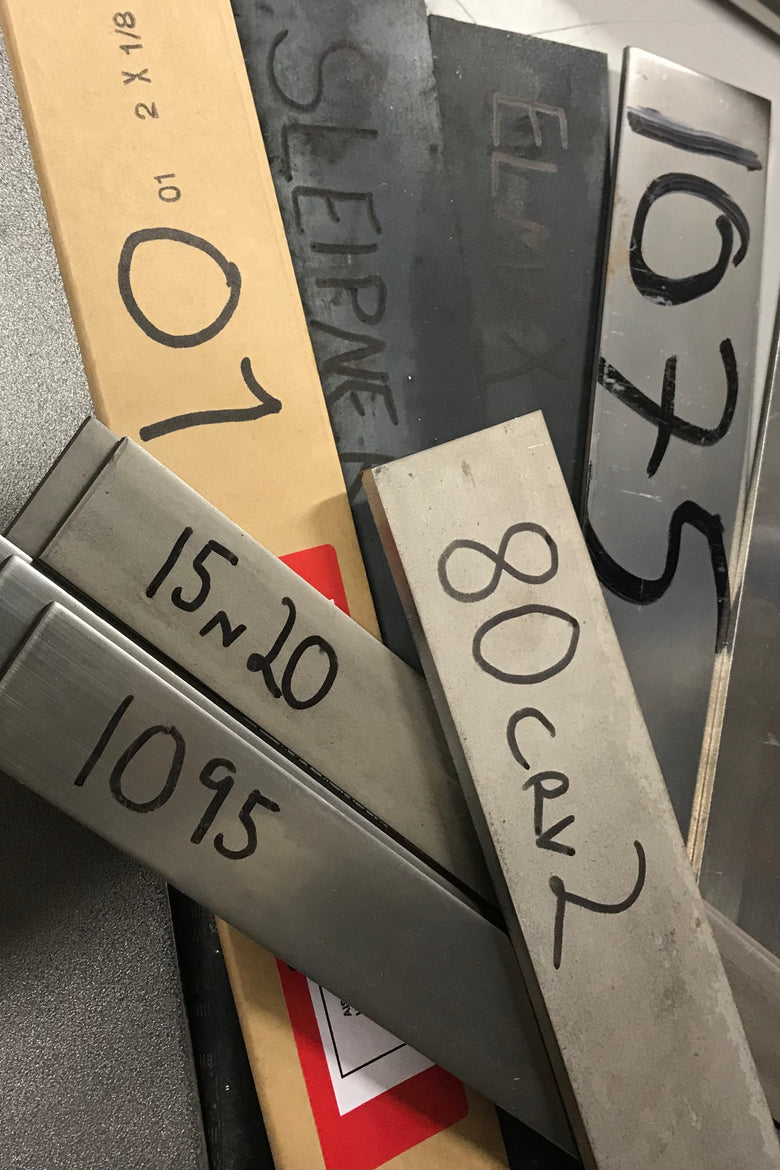

The choice of knife steel is a crucial factor in the performance, durability and ease of maintenance of your knife. When you are making a knife yourself, or want to buy a ready-made knife, knowing the different types of steel will help you make a better choice and ensure that you are satisfied. In this easy-to-understand knife guide, we will go through the properties of knife steel , the most common types of steel, and give you tips for keeping your knives in top condition. Let's start by understanding what makes knife steel so important.

Properties of different types of knife steel

When choosing knife steel, there are several important characteristics that affect how the knife will perform in everyday use. These include:

Hardness

The hardness of knife steel is often measured on the Rockwell scale (HRC). A high HRC value, often above 60, means that the steel is harder, and will therefore stay sharper over time than a steel with a lower HRC. The disadvantage of high hardness is that the steel can become more brittle, and thus more easily break or chip during use. Harder steel is also more difficult to sharpen without good tools and technique. The choice between high hardness and toughness is also important depending on the area of use. In the kitchen when you are going to cut tomatoes and other soft vegetables, hardness is great, while if you are going to hammer into wood, it is often better to prioritize toughness. Therefore, a 56 HRC cleaver is actually very favorable, while Japanese chef's knives are often 65 HRC, which is very hard and brittle.

Toughness

Toughness is about how well the steel can withstand lateral stress, impact and/or bending without breaking. As mentioned, a very hard steel will often be less tough, making it more susceptible to damage during rough use. A tough steel, on the other hand, will be able to handle tougher conditions, but may need more frequent sharpening to maintain sharpness. A tough steel, such as 80crv2, is great and versatile because the edge also benefits from the toughness. It is not only about avoiding the knife itself from breaking, but also that the thin sharp edge avoids breaking off into small pieces. Therefore, toughness is often an underestimated quality in knife steel.

Corrosion resistance (rust resistance)

Corrosion resistance is important if the knife is used in humid environments or for cutting raw materials such as fish or fruit. Stainless steel contains high amounts of chromium, which provides better rust resistance compared to carbon steel. Carbon steel is a general term for steel that has no chromium or less than what is required to be called stainless. More about this difference below.

In addition, it should be mentioned that hardening stainless steel, if you are going to make a knife yourself, is somewhat more equipment-intensive. While you can harden carbon steel in a coal-fired furnace with some added air with a hair dryer, and get the steel up to 800-840 degrees, stainless steels sometimes need to be well over 1050 degrees Celsius and kept at a stable temperature for a long time. Therefore, you should have an electric hardening furnace or access to someone who can harden for you if you want to make stainless knives.

Egg keeping (ability to stay sharp)

Edge retention refers to how long the knife stays sharp in use. That is, how long it takes before you feel you should sharpen the knife again as use wears down the knife edge. Knife steel that has a high hardness and toughness combined will last a long time because the edge is hard and durable, while at the same time being tough enough not to break. However, there is always a balance here, where you have to find the right one based on.

Main categories within knife steel

Carbon steel

Carbon steel is a general term for steel with a low chromium content and its ability to rust. They are also known for their superior sharpness and ease of sharpening. It is a popular choice among traditional knife makers because it provides an extremely sharp edge that lasts a long time, while also being easy to harden in a simple way with minimal equipment. The biggest disadvantage is that carbon steel is more prone to rust, so it requires moisture control by the user with regular drying of the knife, and preferably lubrication with oil regularly or when storing. Carbon steel is ideal for people who want to make a knife that needs to cut quickly and precisely, but are willing to take care of the maintenance. See the contents of one of the classics below: 1075

Stainless steel

As the name suggests, stainless steels have high corrosion resistance. This comes from the chromium content, which reacts with oxygen and creates a thin layer of chromium oxide, which prevents rust. Typically, this chromium content often increases the amount of carbides in the steel, which makes it more difficult to sharpen. Therefore, it is easier to sharpen a carbon steel knife and it often stays sharper than stainless and it is easier to maintain the edge. On the other hand, stainless steel with carbide content can often hold its edge a little longer, but these are generalizations that will vary depending on the steel in question.

As mentioned, they are rust-free thanks to a high chromium content, at least 10.5% but usually more is needed, such as 13% in AEB-L and 18% in Elmax. It is ideal for kitchen knives and outdoor knives that are used in humid conditions or when there is too much stress to keep the knife dry. Stainless steel is easy to maintain due to its rust resistance, but the edge is still often a bit more work to sharpen and maintain.

Powder metallurgical steel

We mention powder metallurgy steels here, not as a contrast to stainless or carbon steels, but as a category of steels that are produced with a special technique that gives particularly good qualities. Powder metallurgy steels, such as Elmax and those produced by CPM (S35VN, MagnaCut, M4, etc.), are an advanced steel grade that gives extra clean and uniform quality, combined with super fine grain size and good carbide distribution in the structure that gives higher performance. It is more expensive than other types of steel, but the quality is higher. Therefore, these steels are often used by professional knife makers in high-quality handmade knives or in more expensive folding knives.

Tool steel

Another term you often find when looking for knife steel is “tool steel”, such as 80crv2, O2 or D2 steel. These steels are often a little more advanced in their content than traditional carbon steels, but can also usually be considered carbon steel, as they will rust. However, they are often added alloying elements such as silicon, molybdenum and vanadium. Although D2 has a high content of chromium, it is not considered stainless. We often find the term tool steel used for steels that fall between the traditional simple carbon steels such as 1075, 1095, 20 steel, and the more advanced and modern stainless steels such as Elmax and MagnaCut. The steels in this category without too much additives and chromium content are often called low alloy. They are not pure carbon steels, but have some additives that increase performance without making them difficult to harden.

A good example of low alloy steel is 80crv2, which has a standard iron content with some additives other than those found in simple carbon steels, so-called unalloyed steels. The result is fantastic performance combined with a simple hardening procedure that can be carried out with good results with little equipment and limited experience. See the content of 80crv2 in the image below, and compare with the slightly simpler composition of 1075 in the image further up.

Usage requirements for different knives

Choosing a steel for a knife mainly depends on the intended use and design of the knife. If it is a large knife that will be used hard in the forest, you will usually choose a different steel than if you are going to have a kitchen knife for a sushi chef.

If you are going to make a knife yourself and are choosing which steel to use in your next knife project, you must look at the equipment you have at your disposal. If you do not have a hardening furnace or someone who can harden for you, high-alloy and stainless steels are not realistic. In that case, you must buy this ready-hardened and grind it very carefully with sharp bands. On the other hand, it is more realistic to focus on carbon steel or low-alloy steels such as 80crv2.

Otherwise, choosing the right steel is about more than just hardness and toughness; it's also about what you plan to use the knife for.

Steel for kitchen knives

For everyday kitchen use, stainless steel is often the best choice due to its corrosion resistance and ease of maintenance. Kitchen knives should be able to handle moisture and acids from food without rusting. Good steels for this are AEB-L and Elmax. In addition, tool steels 52100 and 1095 are popular for kitchen knives.

Steel for craft and forestry knives

Carbon steel or tool steel is a good choice here. They can be sharpened to an extremely sharp edge and can withstand rough use. 80crv2 is a great steel for beginners to pros who want a knife that can withstand hard use.

Steel for hunting and fishing knives

Here you can easily increase the hardness a little at the expense of toughness, as these are used for light work where it is more important to have a sharp knife that lasts than whether it can withstand hard use. Stainless steel is often preferred in these contexts, and powder metallurgical stainless steel such as Elmax is really a huge favorite for use in hunting and fishing knives.

How to keep the knife in good condition

Finally, we will give some tips to ensure that your knife lasts as long as possible, regardless of the steel type.

- Keep your knife clean and dry: Especially with carbon steel, it is important to dry your knife after use to avoid rust. Remember that all knives can rust, even those that are called stainless.

- Even the best knives lose their sharpness over time. Use a whetstone or whetstone when necessary, but learn to use a strap for optimal sharpening and edge maintenance.

- Lubricate the blade : For carbon steel knives, be sure to lubricate the blade with a little oil or wax after use to prevent rust. For stainless steel kitchen knives, it is recommended to wipe the knife with a microfiber cloth to ensure it is clean before storage.

Conclusion

I hope you have gained a little insight into the world of knife steel, and you should know that you can contact us at any time for free advice and tips, we will answer your questions, so send us a message!

When choosing knife steel, consider hardness, toughness, corrosion resistance, and sharpness retention based on your application needs. Whether you prefer carbon steel for its sharpness or stainless steel for its ease of maintenance, the right choice of steel will give you a knife that is perfectly suited to your use. Take a look at our selection of knifemaking steels to find the perfect material for your projects, and feel free to follow us on Instagram for inspiration and tips!

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.