This week we were lucky enough to be visited by the local newspaper Storfjordnytt with journalist Torbjørn Storås! He got a tour and insight into everything we do here, both when it comes to knives, traditional and modern, knife sharpening equipment, wood carving, epoxy glue, epoxy art, composite production and our own testing and product development!

Unfortunately, the article itself about Storbua is behind a paywall, and we of course encourage you to subscribe if you are interested in news from the Storfjord area! For those of you who do not want to subscribe anyway, we can reproduce some points here.

Knife maker and online store owner

In his little free time, Martin works as a knifemaker. In addition to his job and education, he has been involved in online trading through Storbua.no, where he sells equipment for knifemaking, sharpening, epoxy casting and wood carving.

Epoxy and Kydex against masur birch and leather

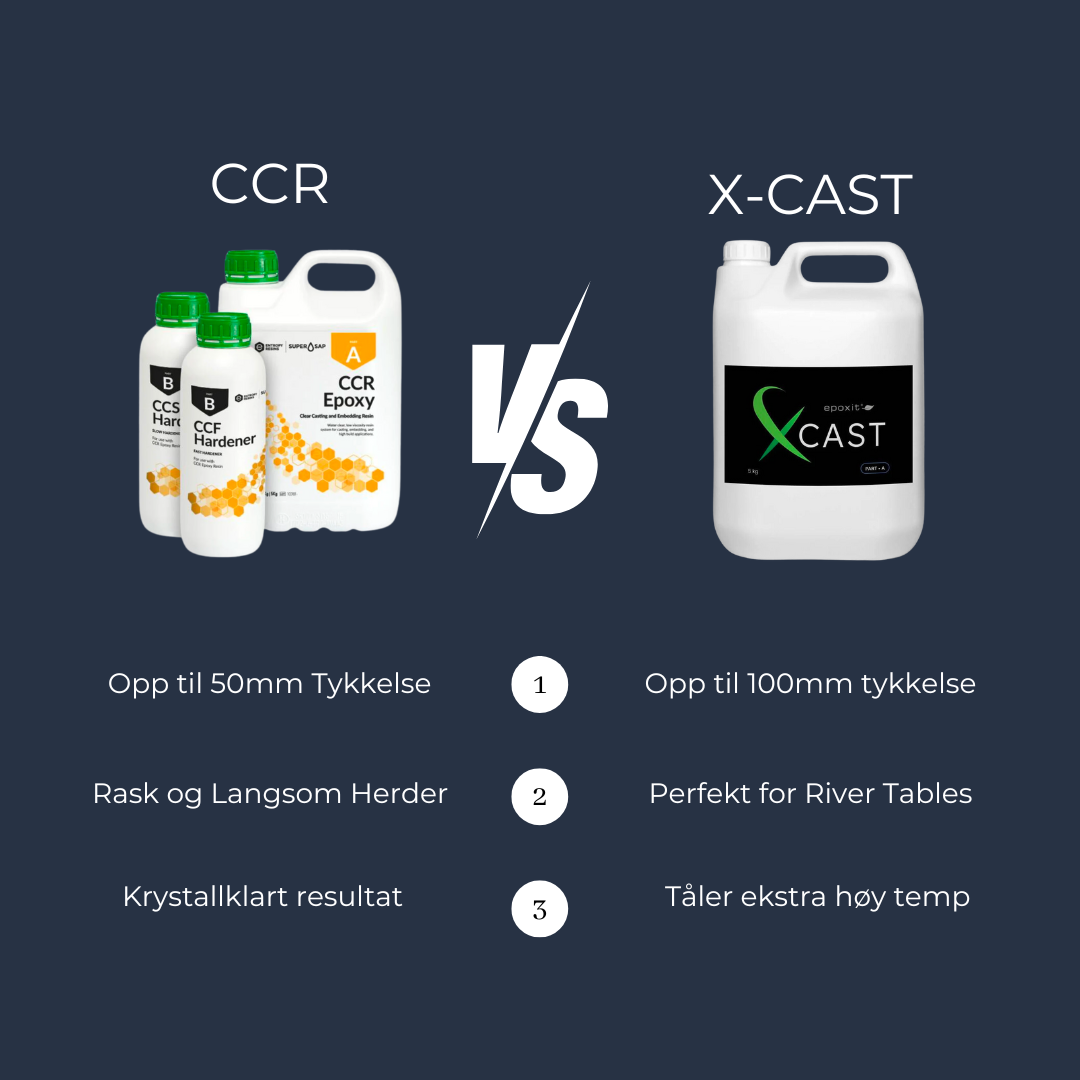

Natural resin has been used to repair clay pots and other objects for thousands of years. Epoxy is a synthetic resin that can be used for casting or as an adhesive; a liquid plastic that hardens when a curing agent is added. Araldite, for example, is a type of epoxy. Epoxy has become popular around the world for casting everything from jewelry and decorative items to large tabletops.

Norway has a long knife tradition

In our long country, people have used knives for as long as we have been here. The knife has had utility in all situations, and the traditional toll knife is both a tool, a stabbing knife and a bearer of history. Some knifemakers believe that traditions have had a bit too strong an influence, which has led to development in Norway being slower than elsewhere. Others believe that new materials such as plastic and modern design are putting a dent in the old craft tradition. That's how it goes these days.

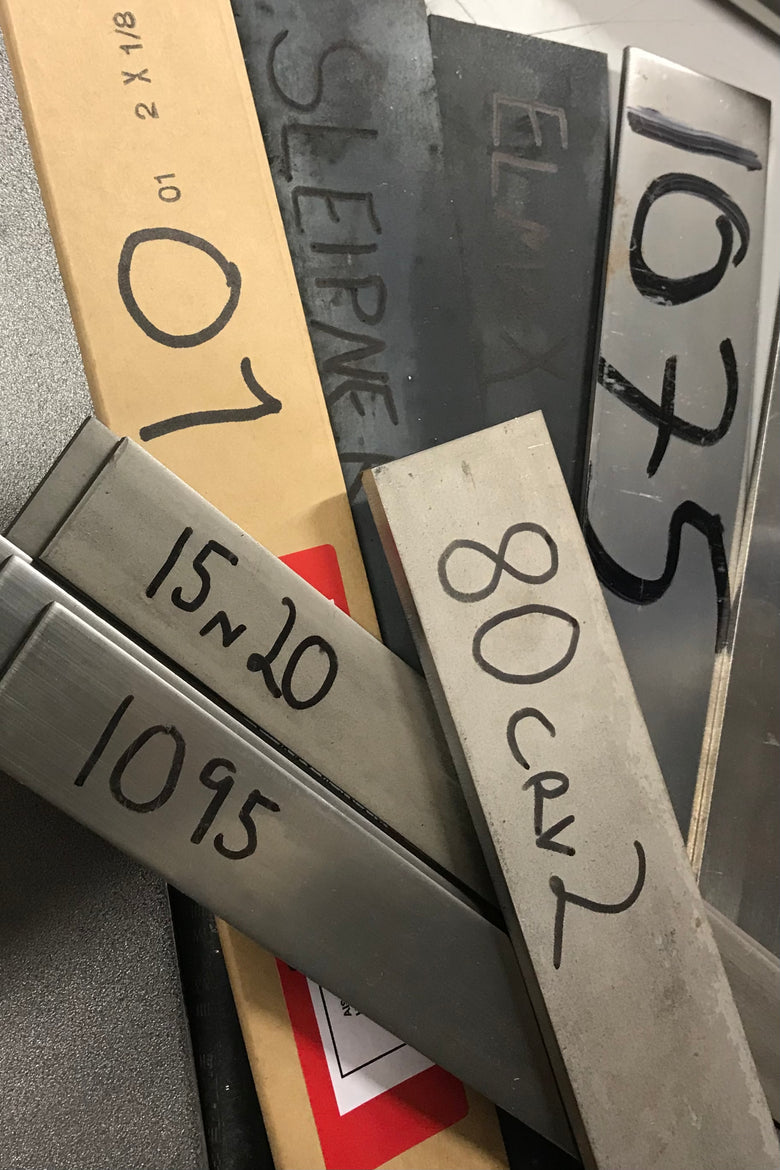

Bigger and a little different across the pond

In the USA, traditions are often less emphasized than here at home, and Americans have a different knife tradition than we Scandinavians. There is more room to think outside the box over there, and knifemakers have experimented more. Although the process and result are often relatively similar, it has long been difficult to obtain what is needed in Norway. Especially if you want higher quality or rarer materials.

Young Martin Flatmo Hove's challenges

The lack of access to materials quickly became a challenge for Martin when he was making his first knives. When you first import, you have to buy in bulk, because VAT and customs can quickly add up to significant costs, and the waiting time can be long. It turned out that there were others who also wanted the same products, and eventually online shopping became a natural way to go to make it easy for other knifemakers and craftsmen to get the products they needed.

Pedro Building – Headquarters of Storbua

Storbua has its headquarters and warehouse in the Pedro building in Stordal. – We are a total supplier of everything for knife making and epoxy art, and it is important for us to have as much experience as possible with the products we sell, so that we can answer all questions from customers, says Martin. The goods Storbua sells should proudly bear Storbua's quality seal. Most people receive their goods within a day or two, and the feedback shows that customers are very satisfied with both the trade and the follow-up.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.