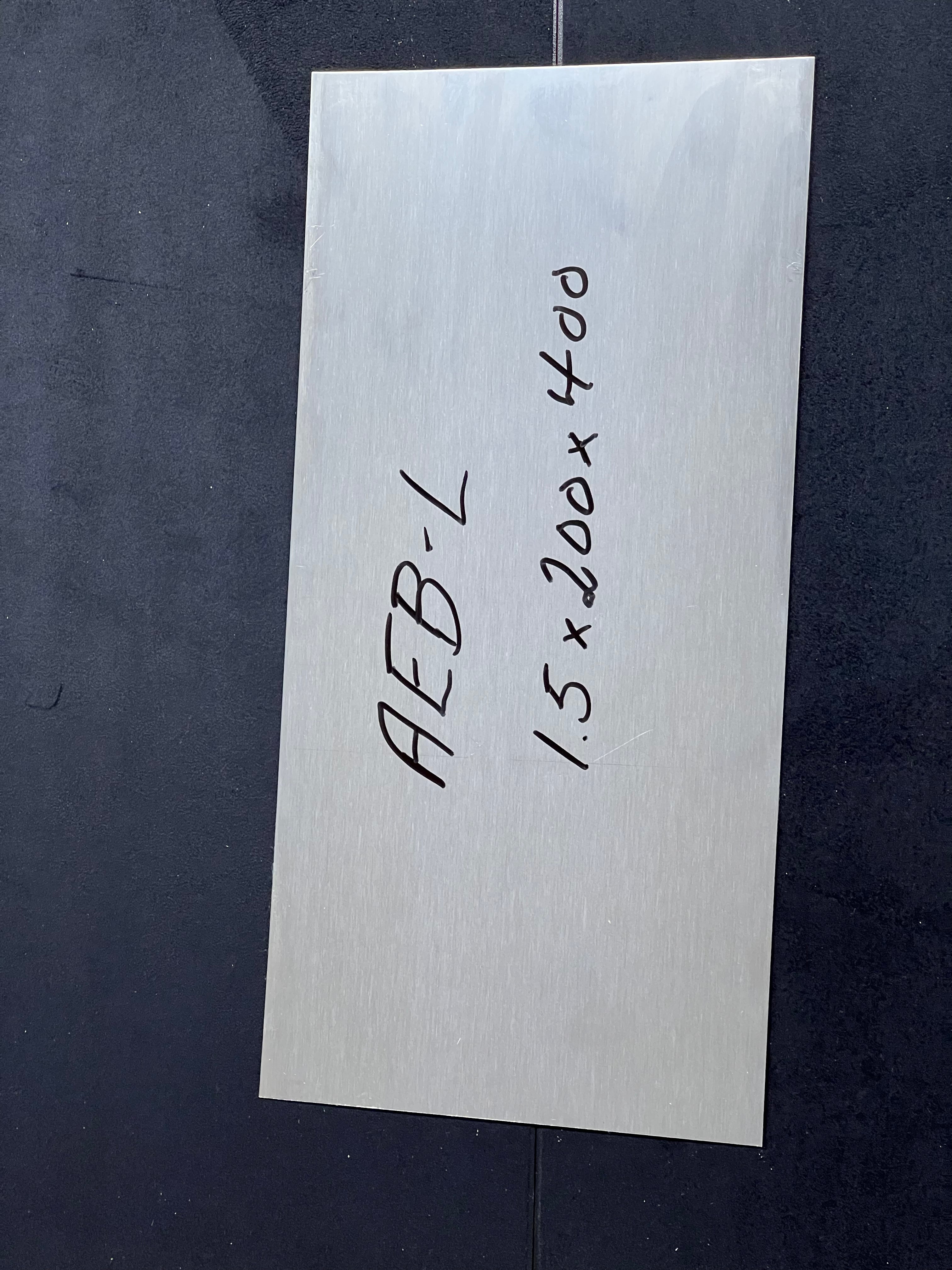

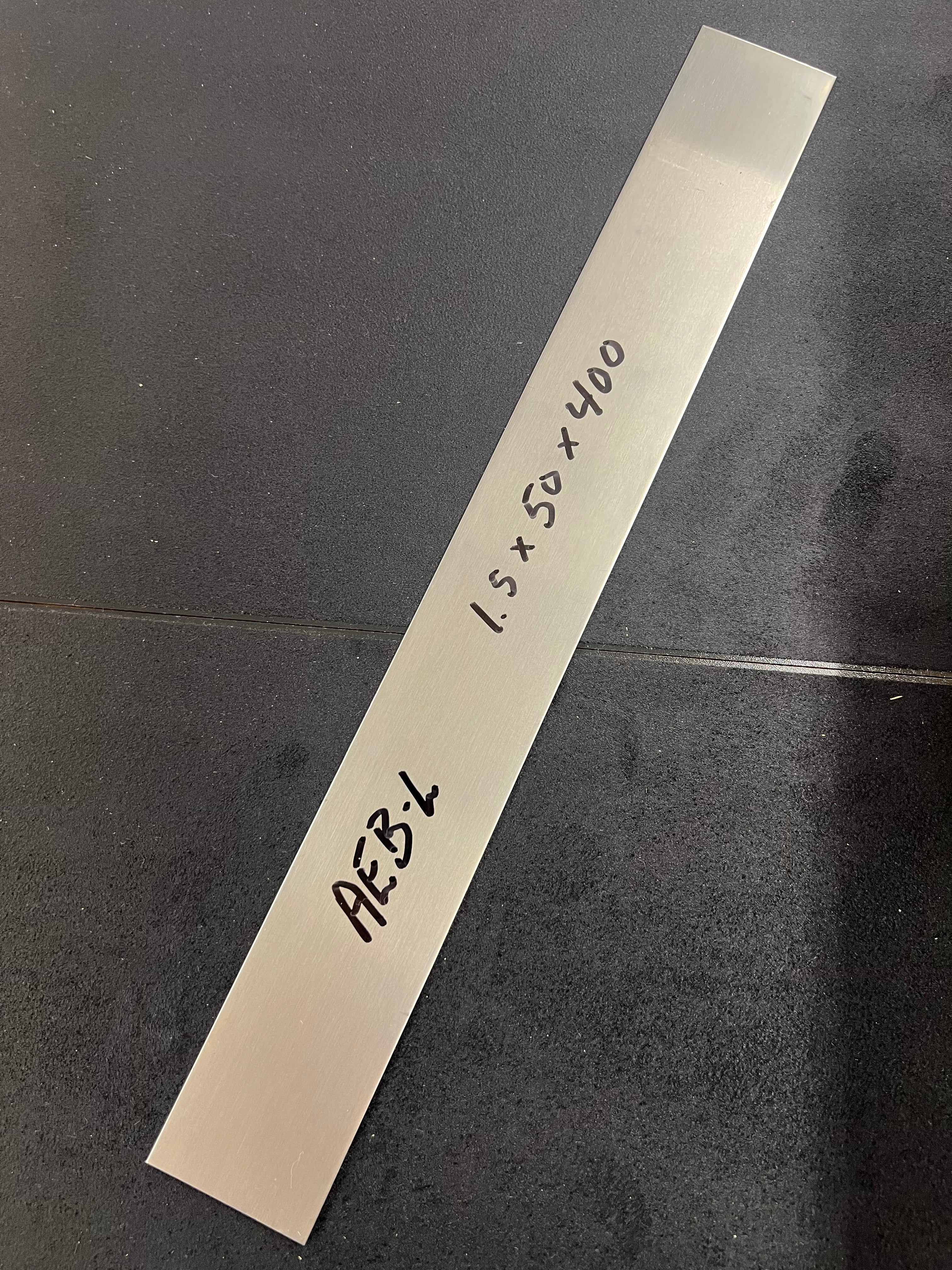

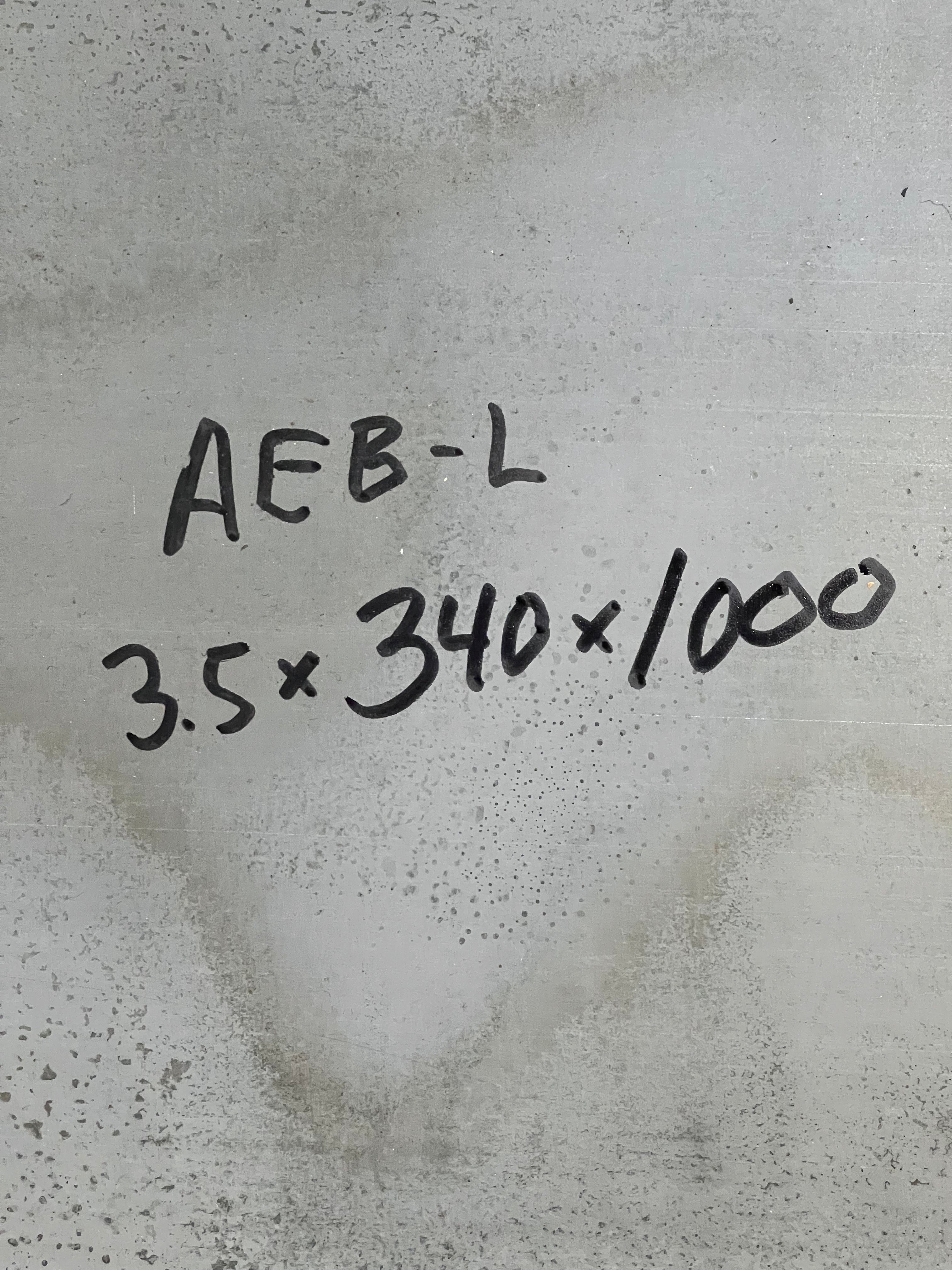

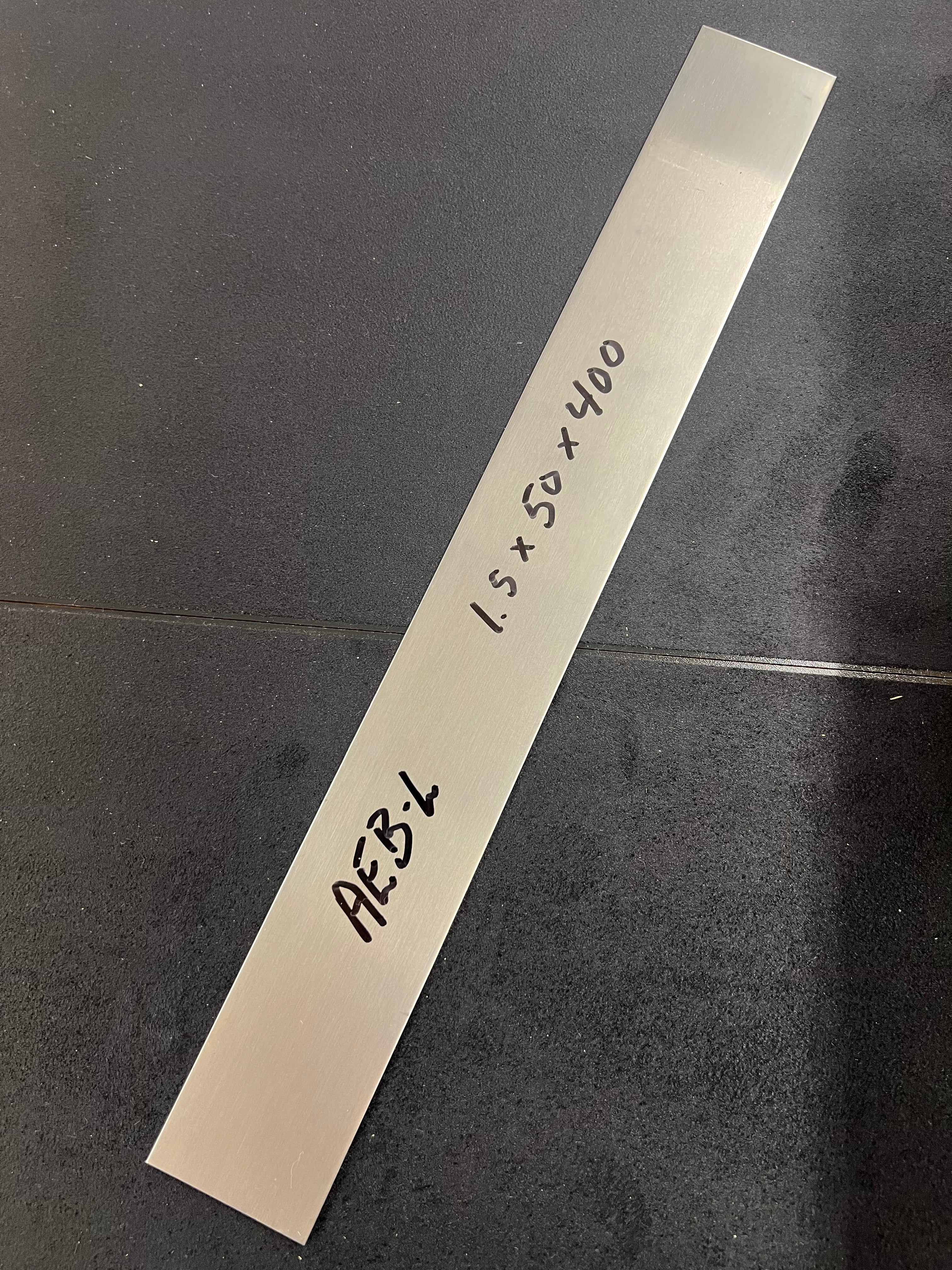

AEB-L Stainless knife steel

Tax included.

Det er risikofritt å handle hos oss

Tusenvis av fornøyde kunder

Rask levering

(1-3 dager)

Kjøp nå,

betal senere

Here you have the well-known AEB-L stainless steel that is just as suitable for the kitchen as it is for the forest. The steel is of super high quality, without having the price of the best “super steels” that are made by a more expensive process.

Can be hardened at 1040 degrees by cooling to room temperature, 1060 degrees by cooling in a freezer or 1080 by deep cooling with liquid nitrogen or dry ice. Such a higher temperature, with deep cooling, will give 1-2 HRC higher hardness, but the performance will still be good without it, as long as the hardening temperature (austenitization temperature) is reduced as mentioned. In any case, we recommend cooling the knife blade in the freezer after it has cooled to room temperature.

We recommend everyone experiment with hardening knife steel to get to know it.

PS: Slightly curved 5-12mm means that this is the height from the table to the highest part of the plate, in the middle, when you place it on a flat table. It has little or nothing to do when making knives and the minimal bend that exists over a knife span (e.g. 25cm) is very small and straightens out when you harden the blade or sharpen it. The other plates are completely flat, so here you can choose freely whether you want to save a few kroner on a plate that has a slightly loose bend or have it 100% flat.

Why deep cooling of stainless steels after hardening?

When hardening stainless steels such as AEBL, it can be advantageous to place the blade in the freezer after oil quenching. For AEBL, a small increase in hardening temperature, and a trip to the freezer after quenching, could result in an increase of 1-1.5 points on the Rockwell hardness scale (HRC). See graph showing the difference between room temperature, liquid nitrogen/dry ice and freezer: https://i0.wp.com/knifesteelnerds.com/wp-content/uploads/2019/02/hardness-AEB-L2.jpg?w=752&ssl=1

Vi sender bortimot alle bestillinger samme virkedag hvis du bestiller før kl. 14.00.

Vanlig leveringstid: 1–3 virkedager med Bring.

Kunder i Nord-Norge kan ta en dag eller to ekstra i noen tilfeller.

Sporing:

Du mottar sporingsnummer på e-post så snart pakken er sendt.

100 % fornøydgaranti:

Vi er helt sikre på at du blir fornøyd. Vi er så sikre at vi tilbyr både full retur og dekking av returfrakt. Uansett. Det er altså helt uten risiko for deg å bestille nå for å inspisere produktet selv i eget hjem og eget tempo.

Vi lagerfører også reservedeler og slitedeler, slik at om du skulle være uheldig å ødelegge noe eller mot formodning greie å slite ut brynene så kan disse enkelt erstattes.

Enkel retur:

Kontakt oss på kundeservice, så sender vi deg en ferdig utfylt returetikett.

Ingen spørsmål – ingen risiko

Beskrivelse:

Here you have the well-known AEB-L stainless steel that is just as suitable for the kitchen as it is for the forest. The steel is of super high quality, without having the price of the best “super steels” that are made by a more expensive process.

Can be hardened at 1040 degrees by cooling to room temperature, 1060 degrees by cooling in a freezer or 1080 by deep cooling with liquid nitrogen or dry ice. Such a higher temperature, with deep cooling, will give 1-2 HRC higher hardness, but the performance will still be good without it, as long as the hardening temperature (austenitization temperature) is reduced as mentioned. In any case, we recommend cooling the knife blade in the freezer after it has cooled to room temperature.

We recommend everyone experiment with hardening knife steel to get to know it.

PS: Slightly curved 5-12mm means that this is the height from the table to the highest part of the plate, in the middle, when you place it on a flat table. It has little or nothing to do when making knives and the minimal bend that exists over a knife span (e.g. 25cm) is very small and straightens out when you harden the blade or sharpen it. The other plates are completely flat, so here you can choose freely whether you want to save a few kroner on a plate that has a slightly loose bend or have it 100% flat.

Why deep cooling of stainless steels after hardening?

When hardening stainless steels such as AEBL, it can be advantageous to place the blade in the freezer after oil quenching. For AEBL, a small increase in hardening temperature, and a trip to the freezer after quenching, could result in an increase of 1-1.5 points on the Rockwell hardness scale (HRC). See graph showing the difference between room temperature, liquid nitrogen/dry ice and freezer: https://i0.wp.com/knifesteelnerds.com/wp-content/uploads/2019/02/hardness-AEB-L2.jpg?w=752&ssl=1